Design Services

Pre-Press

Our team of pre-press professionals ensure your files are ready for the best possible print production.

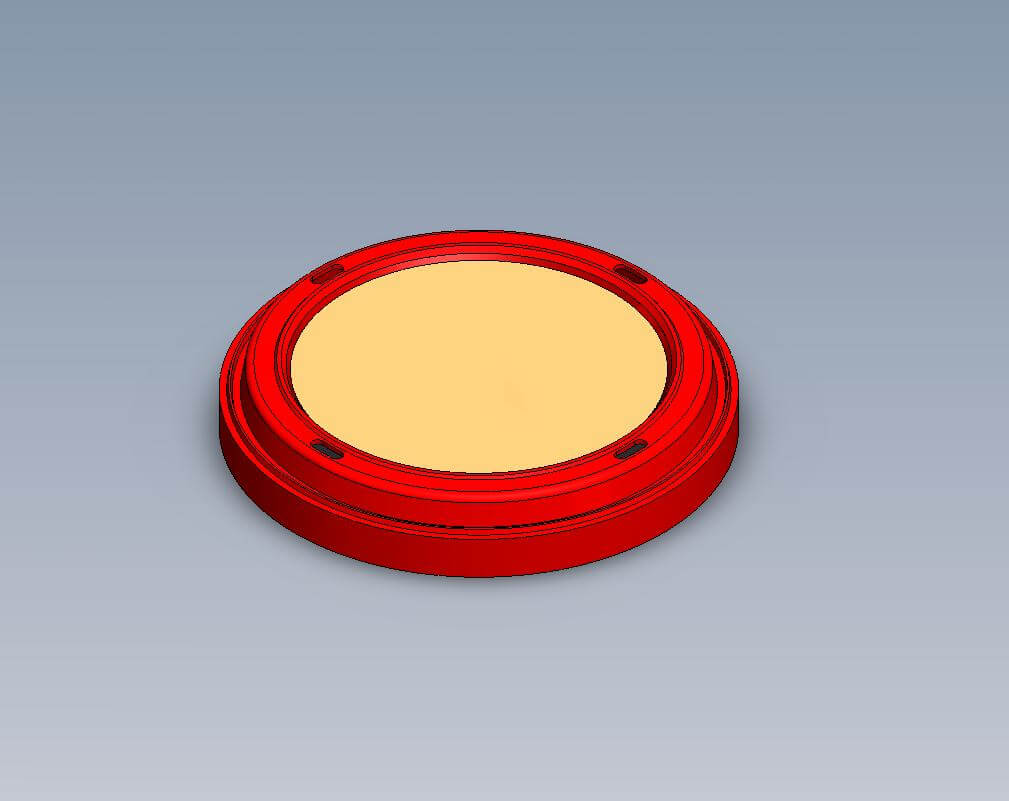

In House Package & Mold Design

Double H Plastics has in-house capabilities for packaging and mold design. With a manufacturing base of hundreds of small tonnage injection molding machines, we build your packaging to the specifications you need, combining the security of plastic closures with the high-quality imaging that can increase your package's consumer appeal. The Double H design engineering team is backed by years of experience guaranteeing safe, error-free products that will exceed your expectations.

In House Tooling & Mold Making Capabilities

For greater appeal and flexibility in packaging, we engineer plastic closures to the exact requirements of any customer. Our value-added package presentations feature secure, easy-open closures. A superior and cost-effective alternative to all-paper or all-plastic packaging, our insert molded design maintains exceptional strength, appearance, durability and enhanced reclosure by the customer. Double H boasts a long history of meeting its customer's exact specifications while maintaining a commitment to HACCP and Food Safety requirements.

Prototyping Capabilities

Double H will work with you, delivering prototypes that match your unique standards while maintaining the integrity and quality of your brand. We manufacture one-up prototypes, stereolithography (SLA) systems, and powder printed models. Our prototyping process enables you to test your end product before it's manufactured, ensuring all expectations are met prior to full-on production.

Get a quote

Whether it's off the shelf or a custom packaging concept, idea, or challenge, contact our experts to start the conversation.

Get a quote