Blog

Posted on November 17, 2020

Do Paper Cups Have a Place Within the Barrier Packaging Market?

Background

Packaging, and food packaging in particular, comes in many shapes and sizes and is created from varying materials based upon intended use. Common food packaging materials such as plastic and paper, while suitable for some products, may not work for others as they allow levels of permeability for moisture, oxygen, and gases that may impact the product. Historically, the solution to this has been a multilayer flexible or rigid structure. On the rigid side, multilayer thermoformed cups or spiral wound fiber/paperboard canisters are typical solutions. Because of the open side seam and the potential for oxygen and moisture to pass through, formed paper cups have not been a viable option. But with additional edge protection and a multi-layer barrier structure, now formed paper cups could be an excellent way to differentiate high barrier products in the market. With this modification, paper cups should not only have a place in the barrier packaging market but they should flourish.

Convenience vs. Sustainability

Barrier packaging, as its name implies, serves to contain and protect product integrity by acting as an oxygen, moisture, and gas barrier. While there is a current focus upon the entire food industry to become more sustainable in its practices and packaging options, there is still a great interest in functionality; specifically extending shelf life in smaller, portable, offerings.

As snacks spike in demand, flexible packaging such as pouches and bags have become a popular option as they offer reclose-ability for on-the-go consumers. Formed paper cups could take this to another level. Cups can stand up on a shelf therefore having better and more reliable merchandising opportunities and shelf presence along with great graphics. Whereas in the past, there has been a tradeoff. Cups may also help to preserve the condition of the product when compared to a bag or pouch as the rigid paperboard offers protection during shipment and handling specifically for e-commerce channels of distribution. Formed cups may also offer improved ease of use for the on the go consumers.

Functionality

In addition to portability, barrier and edge protection prevents grease and oil wicking, ensuring freshness and inhibiting food spoilage. This packaging innovation not only preserves the integrity of the product, but may be utilized to enhance new brands or products, not just replace or compete with existing offerings. This additional functionality could open the door for new and long-standing brands alike to take part in many of the on-the-go or convenient consumer trends, filling multiple segments within a single store.

Paper cups have a place within the barrier packaging market as they offer both convenience for on-the-go consumers and functionality for the preservation of product integrity.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident

Posted on April 8, 2020

Packaging Sustainability

Background

As consumers focus more on sustainability, the plastics and packaging industry has experienced a backlash because of perceived risks to the environment. Whether it’s a ban on plastic bags or plastic forks, consumers are looking for alternatives to single use plastic packaging. Perhaps one of the greatest obstacles being faced directly within the packaging industry is being able to supply the consumer with a sustainable or eco-friendly container that is able to support the product as is intended and meet consumer expectations. In response to growing consumer interest, a number of global consumer packaged goods companies have pledged to move towards 100% recyclable or reusable packaging by 2025.

What Does It Mean?

One of the most difficult aspects of addressing these new consumer expectations for packaging is actually understanding what “sustainability” means. Is the concept of sustainable packaging synonymous with recycling? What truly is a compostable package? Is there such a thing as biodegradable package? Is the understanding unanimous amongst all consumers, brands and the market? The topic of “sustainable” packaging is even more complex when you factor in consumer confusion around the nature of recycling packaging in general.

Materials, Cost & Functionality

The challenge is that often the most sustainable options may compromise the cost and functionality that brands are accustomed to. Replacing polyethylene on a formed paper cup may come with its own performance characteristics. Brands will have to strike a fine balance between the best eco-friendly package without sacrificing a cost effective, reliable product.

Double H & Sustainability

Double H holds several certifications including FSC (Forest Stewardship Council Chain-of-Custody Certification) and SFI (Sustainable Forest Initiative) that support sustainability.

Innovation and exploration into sustainable packaging is a top priority. The company is committed to reducing the amount of materials needed without sacrificing quality or product safety, developing alternatives to replace traditional, non-renewable, or non-recyclable materials, and optimizing freight to reduce the overall carbon footprint.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process, we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident lids. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Thinwall Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.

Posted on July 19, 2019

Functional Packaging – Spoon Lid

Background

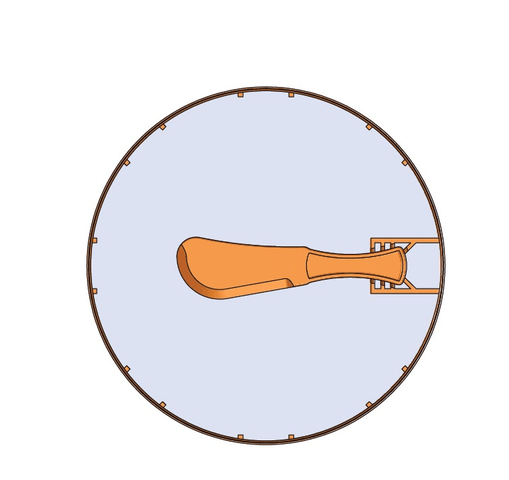

Double H specializes in composite lids; combining an injection molded rim with a printed paperboard insert for the purpose of bringing together exceptional graphics with the function and fit of plastic.

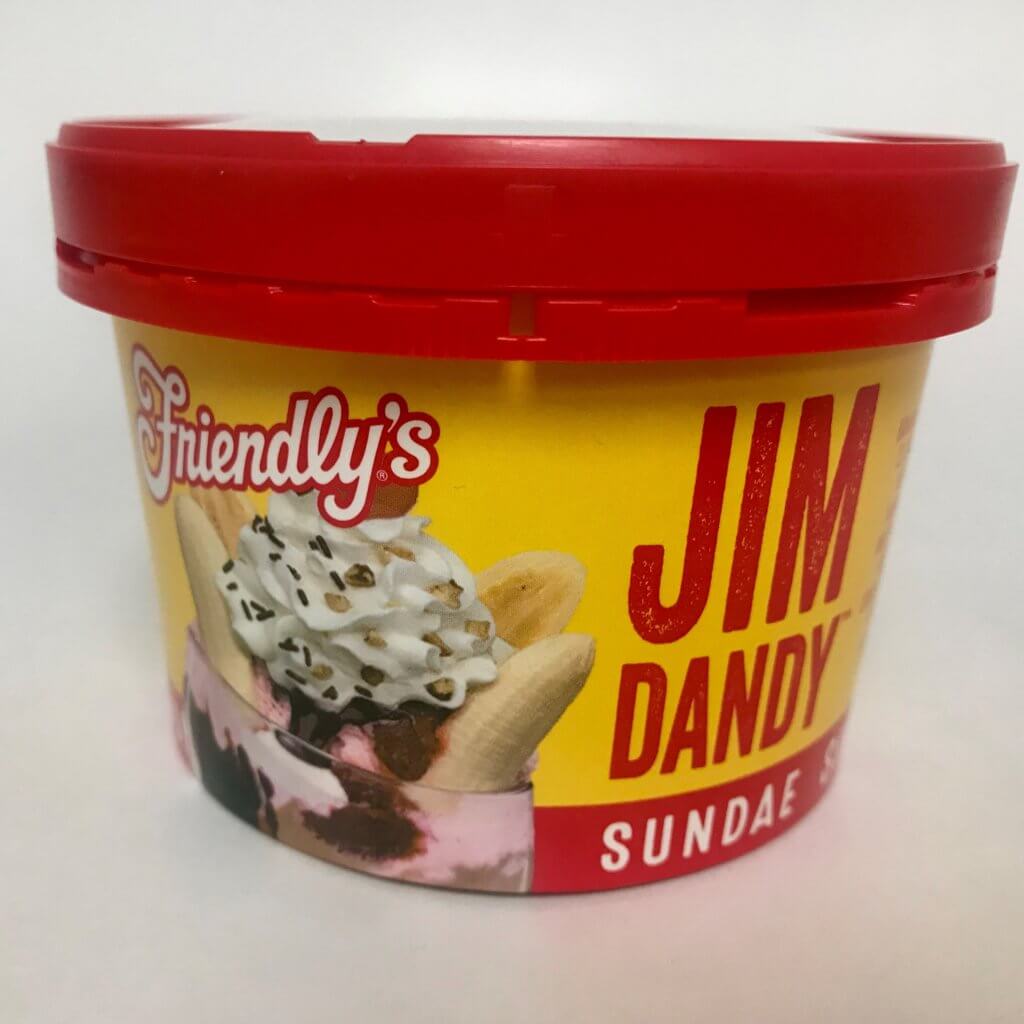

One of the benefits of this technology is the ability to create packaging with additional functionality; like a utensil, on the underside of the lid. The most popular utensil is a “Spoon Lid” for Ice Cream & Frozen Dessert. It’s currently offered in two main sizes, to fit 3.6 ounce and 8 ounce cups, and has been in the market for over 10 years.

Convenience

Consumers are making more and more food and snacking choices based on convenience, and new and innovative packaging can continue to add value. With the utensil integrated into the lid, there is no need for a secondary spoon; which is especially helpful away from home.

Whether it’s portion control or a way to reduce costs, some packages have been downsized so these single serve items don’t need a lid for reclosure. The lid is now utilized as a way to deliver the spoon.

Consumer Experience

While the addition of the spoon as part of the package provides convenience, it is important to note that the food grade plastic should not affect the taste profile of the ice cream. Nothing compares to a real spoon, but for consuming on the go, the plastic spoon is preferred to a wooden spoon option.

Typically, a heat seal membrane is applied once the cup is filled and before the lid is applied. This keeps the spoon clean during distribution and also serves as a form of tamper evidence. From a manufacturing perspective, the lid and heat seal can be applied inline.

The spoon is easily removed from the underside of the lid, rigid enough to use with frozen desserts, and made from a recyclable food grade plastic.

Other Applications

The spoon lid has grown in Ice Cream and Frozen Dessert, but the same concept can be applied in other markets. Similar spoons can be used with edible cookie dough and other savory snacks. Additional designs include a spork for prepared meals as well as a utensil for spreads.

Adding a functionality within the primary packaging allows the consumer to enjoy more products in different ways; in this case, on the move. Whatever the usage occasion, adding a utensil can add immense value to the packaging and the brand.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident lids. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Solid Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.

Posted on May 13, 2019

Tamper Evidence in Ice Cream & Frozen Dessert Packaging

Tamper-evident packaging has been around for a long time but is now more of an expectation, not an exception; specifically, in retail food packaging. Looking more closely at Ice Cream & Frozen Dessert brands, tamper evidence is becoming more and more prevalent.

This is being driven by the retailers and ultimately the consumers as they look for the best possible products. A package that offers some form of tamper evidence is going to provide some additional reassurance.

Not only does this added feature serve the consumer in terms of feeling confident in the integrity of a product, it also assists retailers to ensure that they are filling their shelves with untouched and safe products. While there are many different forms of tamper evident packaging, the goal of safety and security is consistent across the board.

Background

The term “tamper-evident” refers to a device or process that makes unauthorized access to a protected object easily detected. The idea is that some kind of action has to be taken to the package, whether it be to pull a tear band or break off a plastic tab, in order to be able to open or access the contents with ease. The tearing or breaking off of a piece of the container would then serve as the indication to the consumer and/or retailer that this product may have been tampered with and may not be safe for consumption.

Functionality

As defined earlier, “tamper-evident” doesn’t necessarily just refer to one process – as long as it protects the product from unauthorized access then it can be considered to be tamper evident. The most common types of tamper evidence within the retail frozen desserts and ice cream segments are: a heat seal or membrane, a secondary shrink band, or functional packaging.

Heat Seal

Commonly referred to as a freshness seal, the membrane is applied directly to the cup as part of the filling process. It typically requires special equipment but the membrane can be printed and offers brands another chance to convey their message. The consumer would remove the overcap and heat seal prior to consuming.

Shrink Band

Like the seal, the shrink band is a separate component but applied after filling in a secondary operation on a specialized piece of equipment. The clear plastic band can also be printed and would be removed by the consumer in order to access the contents.

Functional Packaging

Unlike the seal and the band, functional packaging incorporates a tamper evident feature into the cup or lid by way of a tab to break or band to remove. In either case, there is a permanent change to the packaging which would indicate tampering. The packaging tends to be more complex but removes a secondary step from the filling process.

What this Means to You

There are a number of proven options available for ice cream and frozen dessert packaging to incorporate some form of tamper evidence. Each situation is different so brands should consider all options and make a decision based on what works best for their product, process, and Consumer.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident lids. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Solid Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.

Posted on March 13, 2019

Composite Lids

Composite, by definition, means “having many elements.” Generally, the composite lid joins an injection molded rim and a printed paperboard insert for the purpose of combining exceptional graphics you would expect from paper with the function and fit of a plastic lid. Composite lids have historically been used with oatmeal canisters, ice cream containers, dry soup products and yogurt cups.

History

Double H started making composite lids in 1985 after purchasing the VersaForm technology. Thirty-four years later, Double H has made the composite lid the cornerstone of its packaging business; producing lids in two locations, Warminster, PA and Marion, IN.

Evolution

There have been many changes over the years to provide solutions for opportunities in the market. From early overcaps and plug styles to a recent lid with an integrated spoon, the composite lid can come in many forms but the goal is the same, to provide a better fit and look. Most recently, Double H launched a tamper evident composite lid. With the tamper evidence built in, the brands can remove a step in the manufacturing process without sacrificing safety and quality.

Composite lids can be designed to partially open and re-close, to have a separate utensil, to have a “window” or use printed plastic inserts in place of paperboard for even better product visibility.

Shelf Presence

A composite lid is stronger than an all-paper lid, holds up better in distribution, and does not tear or separate on the shelf. The paperboard insert can be enhanced with: embossing, de-bossing, foil stamping, special inks or coatings. The insert can be reverse printed with direct food contact inks for printing recipes or coupons and can have game pieces or separate printed inserts attached. Think: contests, specialty market info, and promotion of additional products! The frame of the lid can also be decorated to designate new or limited-edition flavors or special offerings as well as the option for a range of unique frame colors.

Lids can be a great way to promote and to protect your product. With the many enhancements available, lidding can set your product aside from others on the shelf! Please refer to our website www.doublehplastics.com or email packaging@doublehplastics.com with any questions or comments.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Solid Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.